What is the Aluminum Extrusion Process?

Custom aluminum extrusions are created using a unique process that “force-feeds” aluminum alloy through a die. This process allows for a customized cross-sectional profile – much like squeezing toothpaste from a toothpaste tube.

Aluminum extrusion suppliers manufacture and deliver a wide variety of custom aluminum extrusions. Architects, designers, and engineers choose to use custom extrusions due to the incredible design options and unique manufacturing flexibility.

The extrusion die is similar to the open part of a tube of toothpaste. Since that opening has a round shape, the toothpaste will flow out as a "round extrusion." A custom extrusion die will allow for an infinite range of angles, shapes, and channels.

Usage of aluminum extrusions has grown exponentially over the years. And as more industry professionals realize the benefits, the worldwide market continues to grow. Around the world, many more industries are understanding and appreciating the benefits.

Unlimited Extrusion Shapes, Sizes and Angles

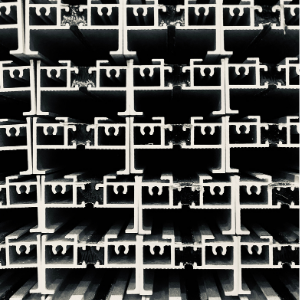

With aluminum extrusions, unlimited shapes, sizes and angles can be customized – from simple design specifications to more complex ones. There are three main categories of extrusions:

• SOLID – this design will extrude without “openings."

• HOLLOW – this design will extrude with at least one “void."

• SEMI-HOLLOW – this design will extrude with partial “voids."

Today, aluminum extrusions are being employed in an ever-growing range of applications, such as automotive, architectural, electronics, construction and aerospace (along with many more).

The Step-by-Step Extrusion Process

Custom aluminum extrusions follow a step-by-step process. For end-users, it’s important to choose an aluminum extrusion supplier that is firmly established with the capacity to satisfy demanding specifications. Another important factor is the capability to provide prompt delivery.

Extrusion Die

Prior to extrusion, an extrusion die must be heated at a high temperature so that an even flow of malleable metal is ensured. Then the extrusion die is ready to load into the extrusion press.

Aluminum Billet

An aluminum billet is a block of aluminum that is cut to size and heated to a high temperature. Once heated, the aluminum billet becomes perfectly malleable, ready for the extrusion process.

Extrusion Press

The heated billet is ready to be transferred into the extrusion press. Lubricants are then added to the press so that the aluminum billet (and any associated equipment) will not stick together.

The “Container”

Once the malleable billet has entered the extrusion press, a specialized hydraulic ram applies pressure to push the billet into the “container”. The material is now ready for extrusion.

Extruded Material

As continuous pressure is being applied, the malleable aluminum is pushed continuously through the die, emerging through its opening. The custom opening creates a profile that’s fully formed.

Cooling Down

The extruded profile now requires cooling as a necessary step – it's sometimes referred to as “quenching." Here, the extruded material is cooled using a water bath or specialized fans.

Shearing Step

Shearing is necessary to separate the extruded profile immediately after extrusion. Once again, the material's temperature is critical because the extruded profile is not completely cooled down.

More Cooling

After shearing, custom aluminum extrusions still require more cooling. Here, the extruded profile remains in place until the extruded material is at room temperature (prior to the next step).

Stretching

During processing, some “twisting” will occur in a profile. Stretching will correct this irregularity. The objective here is to straighten the existing profile to match the specification precisely.

Cutting Step

Once the finished extrusion is straight and fully hardened, it is sawed into specific lengths. The extruded pieces now move to an ageing oven as the process is completed (before any finishing).

When the entire extrusion process is complete, various finishes can be applied to the profile surface to improve the aesthetic appearance. The finishes also provide corrosion protection. Some finishes include powder coating, painting, and sandblasting. All are designed to highlight and enhance the aesthetic finished look of the material. Profiles can be customized further with a wide variety of options, each one to reflect the desired specifications of a given application.

Offshore Direct Metals is One of the Leading Aluminum Extrusion Suppliers

With aluminum extrusion suppliers, it is important to choose smartly. Offshore Direct Metals is a well-established and internationally recognized company. We are known for our high-quality products, our competitive industry pricing, and our just-in-time deliveries. Worldwide, we provide products for a wide spectrum of industries – from automotive to electronics to aviation.

Our client roster includes all types of industry professionals, such as designers, architects, and engineers. Each of them demands the manufacturing flexibility that’s attainable with our custom extrusions. At Offshore Direct Metals, we outperform our competitors with our state-of-the-art manufacturing and our capacity to deliver large quantities without compromising the shipping.

With Offshore Direct Metals, customers are assured of global logistics that allow for the quickest delivery schedules and the most cost-effective shipping. Find out about our company and our services by contacting one of our team members at 1-855-272-3889 or visit our company website at https://odmetals.com. Let us know what you need and we can show you what we can do.

1.855.272.3889

1.855.272.3889  1.365.697.5889

1.365.697.5889