Why Is HDPE the First Choice of Plastic Extrusion Suppliers?

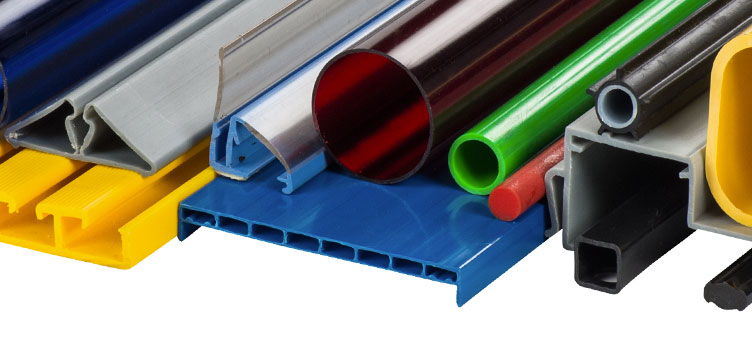

When comparing the best plastic extrusion suppliers, you notice several similarities. One is that top-rated companies consider HDPE the material of choice. As you continue reading, you will begin to understand why. Remember, with such fierce competition among tomers with a superior-quality product is essential,plastic extrusion companies, providing cus which is what HDPE ensures.

What Is HDPE?

HDPE is the acronym for high-density polyethylene. Its unique characteristics and incredible benefits make it the number one choice among reputable plastic extrusion manufacturers. Of all plastics, this is one of the most commonly used. In fact, you come across products every day made from HDPE, including milk jugs, water bottles, plastic grocery bags, food jars, laundry detergent bottles, buckets, cereal box liners, outdoor furniture, and more.

To better understand the value the HDPE provides both plastic extrusion manufacturers and end-users, consider some of the primary benefits.

- Environmentally Friendly – HDPE produces zero harmful emissions during production or use. It also does not leak toxic chemicals into water sources or soil, making it an eco-friendly source of plastic.

- Strength – Compared to another type of plastic called polyethylene, HDPE is much stronger.

- Barrier Qualities – As a barrier against moisture, HDPE is unbeatable. Also, it remains in a solid state even at room temperature, meaning it does melt or show any signs of compromise.

- High-Resistance – For things like chemicals, rot, and insects, this plastic material has a high level of resistance.

- Recyclable – Today, an increasing number of plastic extrusion companies take recycling seriously. Some have adopted special programs that encourage workers and visitors alike to do their part. A growing number of recycling centers and drop-offs throughout the country makes recycling HDPE products easy.

Choosing HDPE Over Other Plastics

With the benefits mentioned, you can understand why so many extrusion companies work with HDPE. With such a broad range of applications, manufacturers of a wide variety of products rely on the same material. HDPE is durable, long-lasting, versatile, and ideal for the molding process. For manufacturing purposes, this plastic has the right degree of toughness, stiffness, strength, ease of forming and processing, resistance to moisture and chemicals, and permeability to gas to make it ideal for endless applications.

Because HDPE is lightweight, it even saves manufacturers money on shipping. For instance, a company that produces outside lawn furniture made of this material will spend less to send finished products to retailers and end-users than furniture made from other plastics and metals. Ultimately, customers enjoy the savings passed down from the extrusion manufacturers. To learn more, or to request a quote visit us online, the leading plastic extrusion company and supplier in the USA.

1.855.272.3889

1.855.272.3889  1.365.697.5889

1.365.697.5889