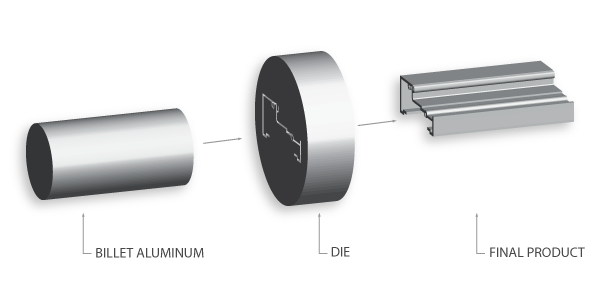

Aluminum extrusion is the fabrication method of producing products by pushing materials like aluminum onto a mold and form the desired shape. Subsequently, custom aluminum extrusion is an aluminum extrusion that’s customized to form specific shapes and materials.

Offshore Direct Metals can build aluminum cross-section matches to its closest final shape that brings down the cost by saving time on matching and lower purchase weight. What can you expect?

- less waste of materials

- faster production

- full customization

- precise and consistent product

- access control over your design

Types of Custom Aluminum Extrusions

There are primarily 3 most popular types of aluminum extrusions that can be custom built to manufacture custom aluminum extrusions.

- Cold Extrusion: The materials used in this process comes in slugs at a room temperature that are forced through a die to fit in, where pressure joins them to produce a desired object in a customized shape. These shapes can be made different processes:

- Lateral extrusion - where liquid materials are pushed in an injection to fit the die shape.

- Forward extrusion – Used to produce solid shapes

- Backward extrusion – Used to produce hollow shapes

- Hot Extrusion: This process involves heating the materials at very high temperatures and then forcing it within the die while still in a melted form.

- Friction Extrusion: The process includes the mechanical twist of the billets based on the die’s position. As the die turns, it produces heat from the metal friction around the opening of the die. Subsequently, the friction and heat allow the metal to go through the die effortlessly and form the desired shape. This manufacturing process is very efficient and obtaining recognition by expert manufacturers in all businesses.

Custom aluminum extrusion is best suited for modern industrial applications. Below is the list of few industries that have seen many benefits from custom aluminum extrusions.

- Automotive Industry

- Construction Industry

- Agriculture industry

- Hospitality industry

- Consumer goods manufacturing

- Transportation industries

- Electronics and computers industries

- Food production and service industries

- Military and defense industries

- Municipal and industrial LED lighting industry

Manufacturing is now more efficient and cost-effective that ever. Custom aluminum extrusion is the most employed and accessible method used these days. Have any questions? To book an expert consultation contact us online or call 1-855-272-3889

1.855.272.3889

1.855.272.3889  1.365.697.5889

1.365.697.5889